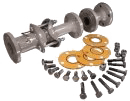

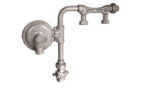

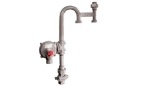

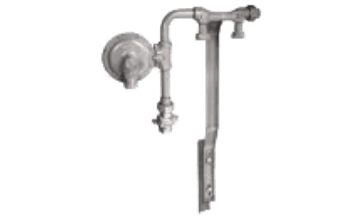

UPSCO’s manufacturing division has since broadened its capabilities to become a one-stop source for conventional and custom fabrications. You can choose from our standard designs or create customized assemblies tailored to your exact requirements. We feature API 1104 code welding, 100% pressure testing, hydrostatic testing, x-ray/mag particle inspection, custom packaging, and custom stocking programs and continued service and support from product development through final installation.

UPSCO coating systems afford our customers outstanding weather resistance with excellent color and gloss retention. Our coatings are electrostatically applied polyester-acrylic and flexible and abrasion resistant. These offer a marine grade application for industry leading corrosion protection.

UPSCO Weld Center of Excellence offers a wide range of support for custom designed specifications including robotic welding systems and welds certified to API 1104 Acceptance Criteria. Our 100% on-site inspection and leak testing is supported by extensive documentation and our own welding procedures.

UPSCO tests 100% of all manufactured parts to ensure products are leak free upon leaving our facility. UPSCO’s testing procedures for threaded connections include pressurized air under water and manometer. For welded connections, UPSCO utilizes pressurized air under water and x-ray (if specified) UPSCO also works closely with outside vendors that specialize in weld inspections. Throughout the production of a part there are visual inspection compared to manufacturing drawings to ensure the cosmetic dimensions are parallel.

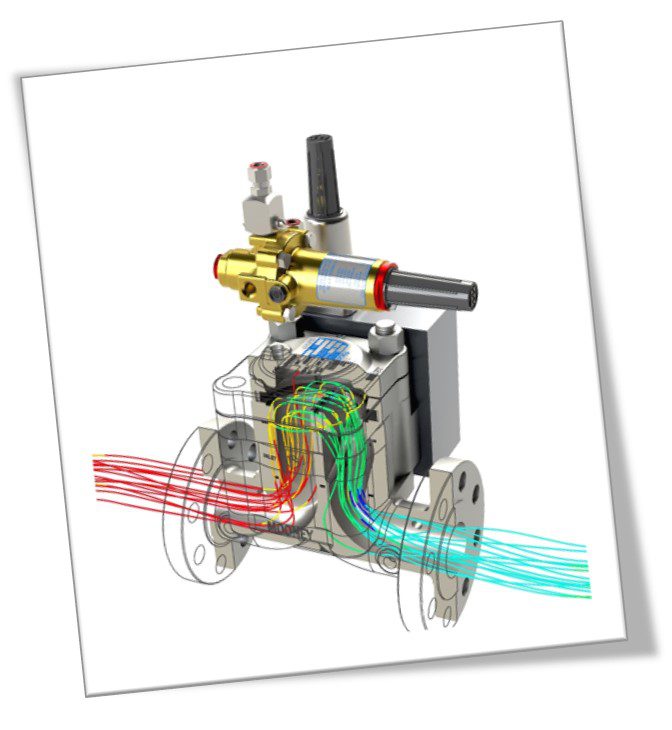

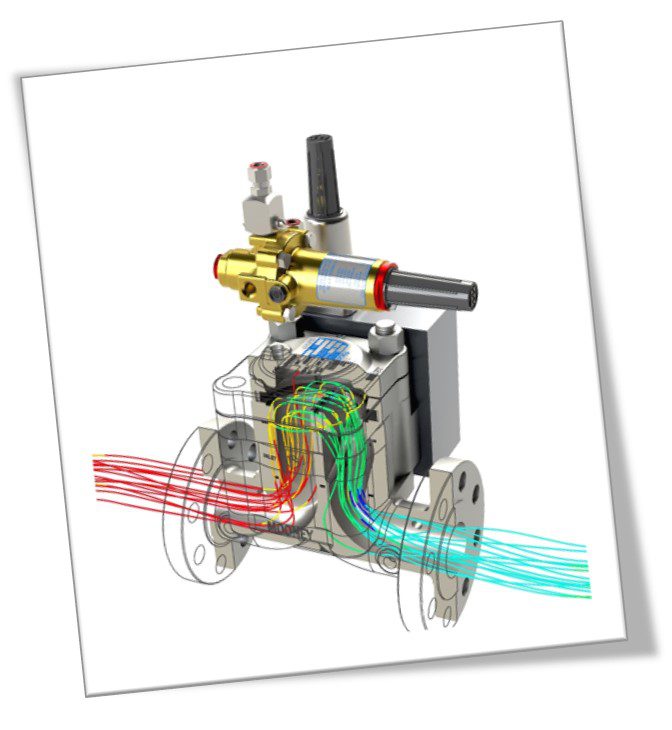

Working from provided drawings and or making new design drawings using state of the art parametric modeling software, making sure all supplied or purchased materials work with the designs, specs & regulations before build even begins.

UPSCO coating systems afford our customers outstanding weather resistance with excellent color and gloss retention. Our coatings are electrostatically applied polyester-acrylic and flexible and abrasion resistant. These offer a marine grade application for industry leading corrosion protection.

UPSCO Weld Center of Excellence offers a wide range of support for custom designed specifications including robotic welding systems and welds certified to API 1104 Acceptance Criteria. Our 100% on-site inspection and leak testing is supported by extensive documentation and our own welding procedures.

UPSCO tests 100% of all manufactured parts to ensure products are leak free upon leaving our facility. UPSCO’s testing procedures for threaded connections include pressurized air under water and manometer. For welded connections, UPSCO utilizes pressurized air under water and x-ray (if specified) UPSCO also works closely with outside vendors that specialize in weld inspections. Throughout the production of a part there are visual inspection compared to manufacturing drawings to ensure the cosmetic dimensions are parallel.

Working from provided drawings and or making new design drawings using state of the art parametric modeling software, making sure all supplied or purchased materials work with the designs, specs & regulations before build even begins.